Somos® 9120™

Every element of the Neo has been carefully considered, always with the customer needs in mind. From manufacturing the Neo with best-in-class components for greater reliability to regular user-driven software updates, the customer is always at the core of the Neo’s development.

The open-system Stratasys Neo800 3D Printer uses Stereolithography (SL) technology to deliver dependable, scalable fabrication at unprecedented speeds. Harness the power and performance you need to create precise parts efficiently and affordably.

Neo Stereolithography printers can create large parts, with outstanding surface finish and high resolution. Part quality is consistent at large volumes and highly repeatable.

Titanium is an easy-to-use software interface that allows users to start builds quickly and monitor throughout the building process. Software updates are driven by customer suggestions and feedback, providing a system that is optimized for customers and their applications.

The Neo line includes a UV curing oven and unloading cart for a seamless post-processing workflow. After printing, the residual resin can be removed using cleaning solvents applied manually or via a semi-automated solution. Once clean, parts cure for an average of 6 minutes per side under UV lamps.

Designed and manufactured by engineers, the Neo800 builds high-quality parts with superior surface quality, accuracy, and detail.

With the Neo®800 you can build high-quality parts with superior surface quality, accuracy and detail.

Exceptional part sidewall quality: Outstanding scanning resolution reduces finishing time by up to 50%.

Measuring 31.5 x 31.5 x 23.6 in., build larger parts without sectioning and bonding.

Compatible with all commercially available 355nm SL resins, allowing freedom of material selection.

Stay connected and updated with the built-in camera, emailed progress reports and status updates.

Customer suggestions and feedback are encouraged, driving user-enhanced software updates.

Remote diagnostics or convenient on-site support from our exceptional service team.

Easy-to-use software optimizes build time and part quality with build history, parameter detail, hardware usage and part traceability data reporting.

The Stratasys Neo800 is carefully designed and engineered throughout, using premium components, parts and finishes.

In partnership with Covestro Additive Manufacturing (formerly DSM) and its Somos,® resins, the Stratasys Neo 3D printers are certified to run the most technically advanced stereolithography (SL) materials.

Somos® resins and Stratasys Neo 3D printers produce SL parts for a wide variety of applications, including prototyping, tooling and master patterns. Somos® resins can be used to print prototypes for concept development and functional testing, as well as applications requiring high heat deflection properties.

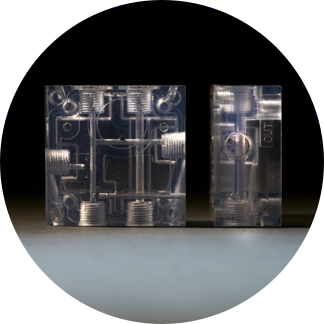

Parts printed in Somos® resins on Neo 3D printers are dimensionally accurate, with an exceptional sidewall finish and sharp feature resolution. The parts require little to no hand finishing, resulting in time savings of up to 50%.

A clear solution delivering ABS and PBT-like properties for stereolithography. WaterShed Black also available.

Ideal for applications that require optical clarity.

Excellent surface quality and isotropy for highly detailed parts.

Designed for easy finishing, produce highly detailed parts with the look, feel, and performance of thermoplastic.

For applications needing strong, stiff, high-heat-resistant composites. Great detail resolution.

Ready-to-use material for PIV wind tunnel testing.

Somos® WaterShed XC 11122’s ABS and PBT-like properties for stereolithography technology make it a popular resin among designers. Somos® WaterShed produces detailed parts with superior clarity and water resistance, well-suited to fluid flow analysis. The durable, clear parts look and feel similar to an engineered plastic, with a smooth finish that accelerates testing time. The material is strong enough to withstand intense wind tunnel testing, making it an ideal choice for the automotive and aerospace industries.

With similar properties and processing to Somos® WaterShed XC 11122, Somos WaterShed Black is a stereolithography resin that produces rigid, tough parts in a true black color, with no need for painting. With its improved formulation, Somos® WaterShed Black has up to a 50% faster processing speed compared to other black SL materials, offering minimal finishing and more consistent processing over time. Somos® WaterShed Black also offers superior moisture and chemical resistance.

Somos® WaterClear Ultra 10122 is a low-viscosity material that produces accurate, functional parts that simulate an acrylic appearance, with minimized finishing requirements. The material is ideal for applications that require optical clarity, like fluid flow analysis, master patterns, and concept and functional models. Somos® WaterClear provides refractive values similar to those of the engineered plastics used for functional testing of optical light transmission work.

Somos® Taurus delivers excellent surface quality and reduces job times for highly detailed parts and isotropic mechanical properties. Somos® Taurus provides the thermal and mechanical performance that once required thermoplastic 3D printing techniques. The material’s higher heat deflection temperature increases its possible applications. The material’s darker color gives parts an added richness that minimizes part finishing and painting, making it a great choice for the automotive and aerospace industries.

Somos® EvoLVe 128 is a durable stereolithography material that produces accurate, highly detailed parts and is designed for easy finishing. The material’s look and feel is almost indistinguishable from finished traditional thermoplastics, making it perfect for building parts and prototypes for functional testing applications and resulting in time, money and material savings during product development. Ideal applications include tough, functional prototypes, snap-fits and jigs & fixtures.

Somos® PerFORM produces strong, stiff, high temperature-resistant composite parts that are ideal for rapid tooling and wind tunnel testing. With the lowest viscosity of any composite stereolithography material, parts made from Somos® PerFORM are faster to build, easier to clean. They also possess superior sidewall quality, with unmatched feature detail. The material’s high heat tolerance, outstanding print resolution and part stiffness make it ideal for high temperature testing, electrical casings and automotive housings.

Somos® PerFORM Reflect utilizes patented new technology that reduces and can even eliminate the finishing work required by traditional materials. Somos® PerFORM Reflect produces strong, stiff, temperature-resistant composite parts ideal for wind tunnel testing. By eliminating the need for additional PIV coatings, Somos® PerFORM Reflect reduces post-processing by more than 30%. Decreasing the overall lead time per design iteration and allowing customers to conduct iterations faster leads to faster data collection.