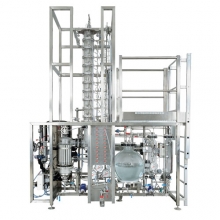

Pignat's standard-size, floor-standing Batch Continuous Distillation trainer (DVI/3000) allows students to operate both a continuous and batch distillation process.

Pignat SAS

Innovative Engineering

Pignat designs innovative training systems worldwide for college and university engineering laboratories. They specialize in high-quality chemical engineering training equipment and offer solutions in various other technical areas. In addition, they design pilot plants for industry, colleges, and universities.

Teaching products include chemical processing, environment, bio-industry, instrumentation and control, fluids dynamics, heat exchanges, pilots+, and mini pilots. With over 60 years of knowledge, they constantly create new units and educational materials. Their continued ability to innovate allows them to improve existing equipment and quality constantly.

Featured Chemical Engineering Training Systems

-

Item Number:DVI/3000

-

Item Number:ABS/100The trainer allows students to study the absorption of NH3 or CO2 in water, determine the material balance of the gaseous solute, influence of operational parameters on efficiency of the column, thermal balance, packing factor, and more. Educational handbook and technical manual included.

-

Item Number:REA/3000Pignat's Computerized Chemical Reactor (REA/3000) is a one-gallon, controlled, multi-purpose, jacketed glass reactor system specifically designed for education and research. This unit supports the study of controlled batch chemical reactions and allows students to operate and experience reaction processes and modify the variables upon which the reactions being studied are based.

-

Item Number:DVI/100Pignat's compact, benchtop Continuous Distillation trainer (DVI/100) allows students to operate a continuous distillation process. Expertly crafted glass components show the flow of fluid through the complete process in both liquid and gaseous phases. With an efficient startup time, steady-state operation can be reached in 20 minutes.

-

Item Number:ABR/3000The regeneration process is observed on the second column, which is continuously fed. An energy‐saving heat exchanger is placed between the two columns to optimize energy usage. With this unit, students are able to study various control loops, determine mass balance, and process efficiency. The unit also includes a LabView monitoring system.

-

Item Number:OTP-DCPignat's Controlled Distillation Unit (OTP-DC) is an automated, controlled, continuous distillation pilot plant. This industrial-scale unit allows students to study unit operations, maintenance, and process supervision.

-

Item Number:RAP/4000This self-contained system facilitates the study of pressure drop due to flow restrictions through valves, strainers, fittings, and pipe of varying diameters, different surface roughnesses, and lengths. The system also facilitates the study of flow rate measurement methods such as orifice assembly, venturi meter, variable-area flow meter, and by calibrated tank vs. time.

-

Item Number:ABS/2000The trainer allows students to study the absorption of NH3 or CO2 in water, determine the material balance of the gaseous solute, influence of operational parameters on efficiency of the column, thermal balance, packing factor, and more. Educational handbook and technical manual included.

-

Item Number:ELL/4000The unit is used manually, with flows controlled by manual valves and flowmeters. The unit has a 2"-diameter glass column, which enhances the visual experience of the extraction process. A pneumatic pulsator increases the contact between the two phases and mass transfer. Students learn how to determine the interphase level, material balance, efficiency of the column, and more.

-

Item Number:ELA/100The unit is used manually, with flows controlled by manual valves and flowmeters. The unit has a stirred glass column, which enhances the visual experience of the extraction process. Students will learn how to determine the interphase level, material balance, efficiency of the column, and more.