Biocompatible Digital ABS Plus

The MediJet™ is setting a new standard for medical printing. With multiple materials and multicolor capabilities, you can create brilliantly vivid anatomical models and drilling and cutting guides* that are sterilizable and biocompatible - all on a certified system. Plus, it’s economical and compact enough for small lab spaces.

Academic Medical Centers, Hospitals, and Medical Device Companies can benefit from the J5 MediJet.

With less upfront investment and a lower total cost of ownership, MediJet is designed to maximize academic medical centers, hospitals, and medical device companies’ investment in 3D printing. The cost per part is 30% lower compared to outsourcing, and the DraftWhite Material the MediJet uses is significantly lower which brings down the cost of single material applications and bulk color models. Additionally, all application needs can be met with this one platform, so there’s no need for multiple printers.

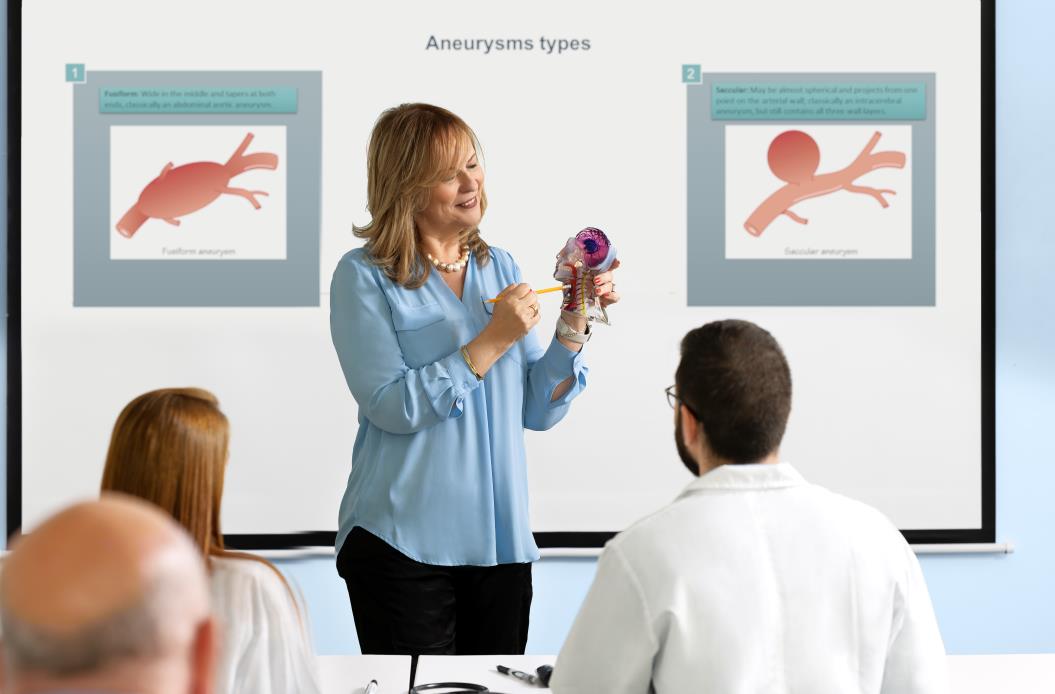

Academic medical centers, hospitals, and medical device companies can create brilliantly vivid pre-surgical planning models, education and training models, medical device development models, and drilling and cutting guides* that are sterilizable and biocompatible.

The MediJet’s large tray accommodates multiple medical models in a single print, requiring significantly less handling and with a 30% faster print time than comparable printing solutions.**

Additionally, GrabCAD Print software streamlines the 3D printing workflow:

Use patient-specific 3D printed medical models for pre-surgical planning to help improve patient outcomes, patient understanding and consent.1,2,3.

Print exact pathology on-demand and train physicians, students and medical device field staff anywhere.

Create drilling and cutting guides* that are sterilizable and biocompatible.

*With approved 3rd party 510k cleared segmentation software.

Enable clinically relevant benchtop testing and create consistency by 3D printing exact anatomy to use when testing medical devices.

The use of patient-specific 3D printed medical models for pre-surgical planning improves patient outcomes by reducing complications, decreasing operation time and length of hospital stays. Patient understanding, consent and satisfaction have also improved using 3D medical models. 1, 2, 3.

Print patient-specific models on demand for education programs. Scale up product demonstrations when training field staff and physicians on a new medical device.

Create consistency in testing to enhance product quality, reduce costs and accelerate time to market.

The J5 MediJet is 510K cleared by the Food & Drug Administration for clinical diagnostic use with leading segmentation software companies. It is biocompatibility certified for limited contact to tissue and bone, and permanent contact to intact skin (ISO 10993), and for breathing gas pathways in healthcare applications (ISO 18562). MediJet models can also be sterilized using Steam, Gamma, and EtO methods specific to the print material.

*with approved 3rd party 510k cleared segmentation software.