LOCTITE® 3D 3172 High Impact by Henkel

A transformative 3D printer enabling mass production of end-use parts in a diverse range of high-performance materials. Achieve industry-leading accuracy, consistency, detail, and throughput with the P3™ Programmable Photopolymerization technology. Get ready for a new era of 3D printing.

An evolution of digital light processing, P3 powers the Origin One. The tightly synchronized print process includes pneumatic controls to reduce pull forces during the print process, resulting in exceptional surface quality, without sacrificing speed or isotropy. Coupled with an advanced 4K light engine, P3 enables the highest 3D printed part quality and throughput the industry has seen.

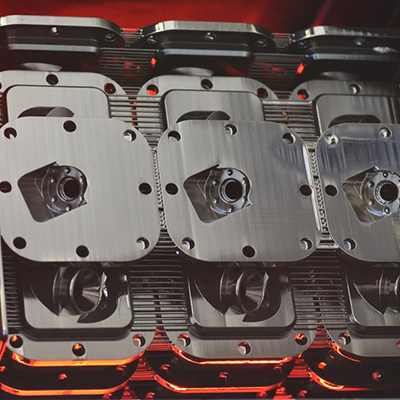

An optimized build volume (192mm x 108mm x 350mm), compact footprint (400mm x 450mm x 1100mm), and minimal power requirements enable manufacturers to efficiently maximize production capacity per sq ft.

From biocompatible medical devices to aerospace-grade components and everything in between, Origin One enables breakthrough production applications. Discover how Origin One customers have harnessed P3 technology and materials from Stratasys material ecosystem partners to extend capabilities and create new business opportunities.

Origin One’s P3 technology utilizes computer vision and 25+ environmental sensors to monitor and respond to every important aspect of the print process. In situ analytics, combined with automatic pressure, pull force, and temperature regulation, ensure the first part is the same as the last. See powerful product improvements over time, with over-the-air software updates that unlock new advanced materials and workflow optimizations.

It takes an ecosystem to transform an industry. Stratasys works with leading chemical companies to co-develop innovative photopolymers in several categories to unlock end-use applications in 3D printing. Choose from a wide range of single component, commercial-grade materials, developed on and validated for Origin One. Resins are engineered to be easy to handle and rapidly post-processed, with long shelf lives.

Materials for application specific requirements such as flame smoke and toxicity, HDT or mold durability.

Impact resistant resins for functional applications that need to perform under stress and high-load conditions.

Fast printing materials for end-use applications requiring cosmetic surfaces, fine features and high accuracy.

Resilient high-resolution elastomers for applications requiring excellent tear strength or rebound performance.

Medically certified materials for devices where aesthetics, durability and biocompatibility are critical.

Choose from application-specific materials that have proven performance and come with industry-standards testing data.

An optimized build volume, compact footprint, and minimal power requirements enable manufacturers to maximize production capacity per sq ft efficiently. Scale up production with modular hardware and post-process in minutes versus hours to produce parts at scale.

Gain ultimate production flexibility with short or long builds and fast material swaps. Easily print features as small as a hair or solid large molds in the size of the build area with the same exceptional accuracy and consistency.

Achieve a low per-part cost with a fast time to part, affordable single component resins, minimal post-processing, low waste and high production yields. Seamlessly move from prototyping to production on the same platform.