Lockout Tagout Training System, Single Block & Bleed

A typical industrial facility features a wide variety of energy sources, such as electrical, mechanical, hydraulic, pneumatic, chemical, and thermal energy, in machines and other equipment. These various sources of energy present a potential hazard to workers. For example, the unexpected, uncontrolled release of stored energy can cause serious injury or even death to workers during the maintenance and servicing of equipment and machines.

Properly executed lockout/tagout (LOTO) procedures can protect workers from hazardous energy releases. These procedures ensure that workers carefully disable potentially hazardous energy sources before performing maintenance or servicing machines or equipment to prevent accidental or unexpected start-ups.

Lockout/tagout procedures should include the following six basic steps: preparation, shutdown, isolation, lockout/tagout, stored energy check, and isolation verification. Following proper lockout/tagout procedures ensures that workers can safely service and maintain equipment without fear of the unexpected release of stored energy.

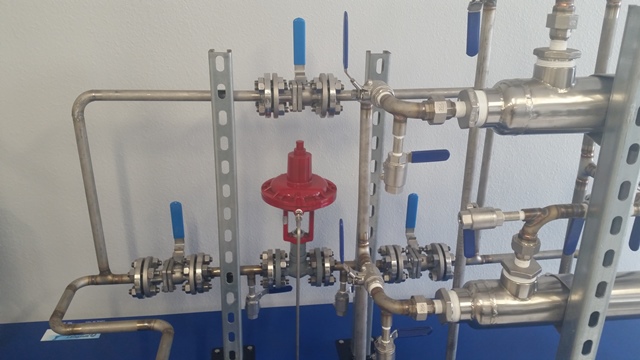

Bayport Technical's Lockout Tagout Training System, Single Block & Bleed (150-LOTO1B), was designed to provide hands-on safety training for a wide variety of common process activities, both mechanical and electrical.

This LOTO unit is capable of demonstrating the necessary procedures of locking out different valves or parts of the equipment in order to isolate individual sections. The unit can also demonstrate electrical processes involving the isolation of switch boxes via breaker boxes and switches.