Gecko Single Pad Gripper

- Compact, lightweight Gecko Single Pad Gripper requires no cables, electricity, air, or programming for cost-effective, plug-and-play performance

- Innovative adhesive gripper for flat, smooth, or perforated objects automates tasks that were previously not possible

- No-mark gripping even for shiny surfaces - cleaning step is not required, saving time and improving productivity

Why Gecko Single Pad Gripper?

The Gecko Single Pad (SP) Gripper brings the innovative Gecko adhesive gripper technology to small-footprint applications that were previously impossible to automate. The gecko-inspired adhesive technology offers precise, no-mark gripping, even for perforated items such as circuit boards or for shiny surfaces, without the cleaning process. Named after their payload in kilos, the three different Gecko Single Pad grippers (SP1, SP3 and SP5) work with leading small robots and cobots. The compact, single-pad design allows easy workpiece accessibility, even in tight spaces. With no electronics or air supply needed, the Gecko SP is a cost-effective, true plug-and-play solution. Seamless integration with the robot of your choice.

LOWER OPERATING COSTS, HIGHER ROI

Leaves no marks on the glass so no manual cleaning required.

FASTER, MORE PRODUCTIVE SOLUTION

No wires or external air supply needed.

EXTENDED AUTOMATION POSSIBILITIES

Can grip even perforated workpieces such as printed circuit boards, aluminium mesh or head gaskets.

Advantages and Features

Gecko SP gripper offers no-mark automation for flat, shiny, and perforated workpieces without electricity or air supply required. The Gecko SP is available in three sizes; SP1, SP3 and SP5 named after the gripper’s payload in kilos, featuring ability to lift a wide range of flat, smooth, shiny or perforated surfaces. Because the technology doesn’t mark even high-shine surfaces, it eliminates the need for a cleaning step in manufacturing processes, saving time and improving output. Similar to its larger sibling, the Gecko SP can grip even perforated workpieces such as printed circuit boards, aluminium mesh or head gaskets.

COMPACT, LIGHTWEIGHT, AND FLEXIBLE

The small, single-pad design allows easy workpiece accessibility, even in tight spaces.

NO WIRES OR AIR SUPPLY NEEDED

With no electronics or air supply needed, the Gecko SP is a cost-effective, true plug-and-play solution.

NO-MARK GRIPPING FOR SHINY WORKPIECES WITHOUT SUBSEQUENT CLEANING

Our gecko-inspired adhesive technology offers precise, no-mark gripping, even for perforated items such as circuit boards or for shiny surfaces.

AVAILABLE FOR 1KG, 3KG, 5KG PAYLOADS

Gecko SP is available in three sizes; SP1, SP3 and SP5 named after the gripper’s payload in kilos, featuring ability to lift a wide range of flat, smooth, shiny or perforated surfaces.

LITTLE OR NO PROGRAMMING REQUIRED

The gripper comes with pre-integrated software that is easy to install and program, so even employees with no technical background can set it up.

POWERFUL GRIPPING FOR PERFORATED WORKPIECES

The Gecko SP can grip even perforated workpieces such as printed circuit boards, aluminium mesh or head gaskets - extending automation possibilities.

Applications

Material Handling

Material Handling

No-mark gripping technology for pick and place processes. Even objects that are perforated can be picked up easily. A small, compact gripper solution for your collaborative application.The small, single-pad design allows easy workpiece accessibility, even in tight spaces.

Accessories

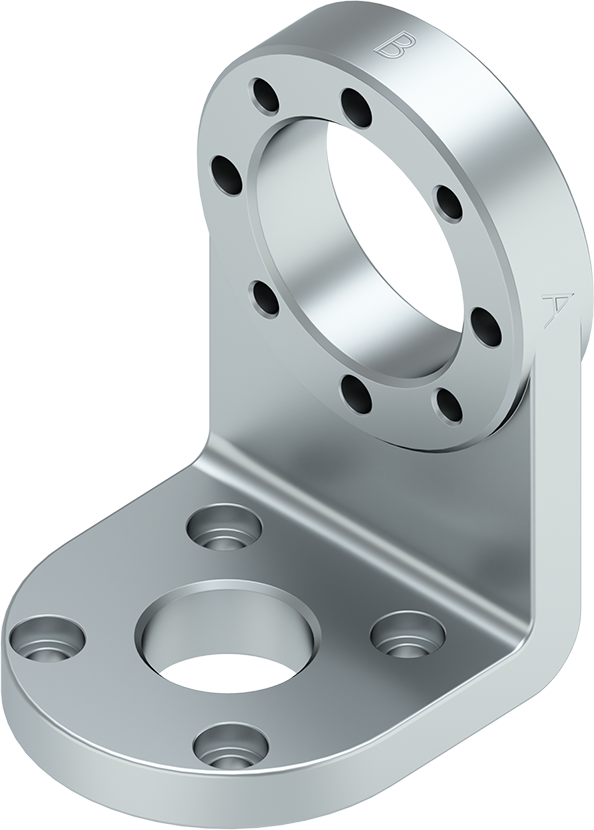

Angle bracket - 90 deg

Enables the user to attach tools at a 90 degree angle to the robot flange. This improves the tool's ability to fit into tight spaces and lowers the risk of the robot arm going into singularity.