Extended Vibration Analysis Training System

Industrial maintenance technicians must learn to operate, maintain, troubleshoot, and repair a wide variety of mechanical systems used to manufacture products. One of the key diagnostic tools technicians will use during preventive maintenance as well as to maintain optimum efficiency is vibration analysis.

Excessive vibration detected during routine monitoring can signal a potential problem that can be remedied before a breakdown occurs. Vibration analysis can also be used to finely tune systems to ensure they’re working at peak efficiency. Vibration analysis plays an important role in various industries, from HVAC and automotive to oil and gas and food and beverage.

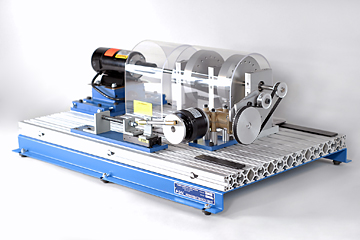

DAC Worldwide’s Extended Vibration Analysis Training System (203E) is a versatile, precision-machined, rotating device for teaching advanced vibration analysis in industrial rotating machinery. Learners using the trainer can isolate individual, vibration-causing variables in order to distinguish and identify their unique signatures.

Industry-Standard Components Provide Realistic, Hands-On Training

Technical training is most effective when learners can gain hands-on practice with industry-standard components they’ll encounter on the job. The Extended Vibration Analysis Training System features common, industrial-quality components to provide learners with a realistic advanced vibration analysis training experience that will build skills that translate easily to the workplace.

The Extended Vibration Analysis Training System is a sturdy unit that features a 1/3 HP, 3450 RPM, inverter-duty, 3-phase, AC motor with precision SCR speed control and a digital RPM indicator with magnetic pick-up.

Some of the industrial-quality components learners will find on the trainer include: t-slotted, modular work surface; indexing pins; CNC-machined pillow blocks; jack-shaft; right-angle gear reducer; adjustable magnetic brake; connecting arm/linear slide mechanism; and precision-machined rotors.

Standard accessories included with the training system include: Allen wrench set; combination wrench set; balancing weight/washer set; clay; vibration isolating feet; resonance demonstration kit; spring/weight demonstration kit; balancing phase target; and shim stock.

The system requires 110/220 VAC, single-phase electric. It also requires the #203-003 Basic Vibration Meter.

Courseware & Hands-On Exercises

The Extended Vibration Analysis Training System’s courseware consists of a user’s guide with hands-on exercises. These can be used as part of either an instructor-led course or self-directed study for maintenance technicians to learn advanced vibration analysis fundamentals, vibration measurement, vibration causes, data collection, and balancing.

Learners will explore a wide variety of fundamental topics, including effects of frequency and displacement; illustrating resonance; understanding critical speed; proper pickup mounting; understanding imbalance; understanding vibration caused by misalignment; witnessing vibration from bearing faults; witnessing looseness; calculating the effects of imbalance; and single plane balancing.

Expand Training Capabilities with Custom Options

The Extended Vibration Analysis Training System can be customized with a wide array of options to create a training system that matches a particular industry’s or user’s specific needs. In industry, one size rarely fits all and this trainer can be tailor-made to your exact needs.

For example, the training system’s capabilities can be expanded by adding one or more of the following options: resonance and elastic shaft kit; gear fault accessory; shaft alignment tool kit; magnetic base/dial indicator set; electromechanical workstation; vibration analyzer; eccentric/cocked rotor kit; journal bearing kit; crack demonstrator kit; pump cavitation demonstration accessory; fan demonstrator set; motor fault kit; and load/brake device accessory.