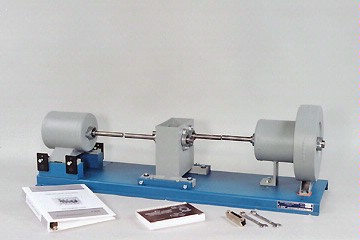

3-Component Coupling Shaft Alignment Training System

Basic mechanical maintenance skills are fundamental throughout advanced manufacturing and a wide variety of industries. For example, industrial maintenance technicians must possess essential knowledge and skills to perform shaft alignments and maintain, troubleshoot, and repair a variety of couplings.

DAC Worldwide’s 3-Component Coupling Shaft Alignment Training System (206-000) is a heavy-duty, precision-crafted training system that teaches learners the basics of shaft alignment. The system trains learners in all of the common alignment techniques and tools they’ll encounter on the job.

The system requires the #208-015 Magnetic Base/Dial Indicator Set and #208-001 Tool Kit. It also includes the following: driver, gearbox, and driven elements, flanged bearings, replaceable shafts, toolset, #510-000 IPT Industrial Trades Training Manual, and #206-500 Use/Exercise Guide.

The system is patterned after a typical turbine-driven pump or turbo-compressor. In addition, each element of the system and its shaft can be adjusted to create unique alignment problems to simulate real-world situations learners will encounter with multiple-element equipment used in an industrial setting.

Industry-Standard Components Provide Realistic, Hands-On Training

Technical training is most effective when learners can gain hands-on practice with industry-standard components they’ll encounter on the job. The 3-Component Coupling Shaft Alignment Training System features a variety of common, industrial-quality components to provide learners with a realistic training experience that will build skills that translate easily to the workplace.

The 3-Component Coupling Shaft Alignment Training System is a sturdy unit mounted on a formed-steel baseplate with a heavy-duty, welded aluminum driver, gearbox, and driven elements. Some of the industrial-quality components learners will find on the trainer include flanged bearings that allow changes in angular and parallel misalignment; motor attachment points with steel-threaded inserts; replaceable shafts to allow easy installation of bent shafts; 3/4”-diameter shafting with keyways; steel pads with jacking bolts; and sets of Allen and combination wrenches.

The system also includes supplemental “long span” shafting that allows for 3-element offset, in-line, and “long span” alignment circumstances. The system’s rigid construction allows precise alignment to .001”.

Courseware & Hands-On Exercises

The 3-Component Coupling Shaft Alignment Training System’s courseware consists of an IPT Industrial Trades Training Manual with chapters on couplings and alignment technique and a user’s guide with hands-on exercises. These can be used as part of either an instructor-led course or self-directed study.

Learners will explore a wide variety of fundamental couplings and shaft alignment topics, creating a complete, in-depth, hands-on course in precision alignment techniques for multiple-element equipment used throughout industry.

Hands-on exercises include industry-relevant skills, such as coupling/shaft alignment terminology and theory; use of a dial indicator in coupling/shaft alignment; coupling alignment pre-checks; locating and correcting soft foot; calculating and correcting for bar sag; coupling alignment using multiple methods, such as a straight edge and thickness gauge, the rim and face method, and the reverse dial indicator method (one or two dials); using graphical solution techniques with the rim and face method and the reverse dial indicator method; considering thermal growth in shaft alignment; inspection and installation of shafts and keyways; fabrication and installment of shaft keys; and assembling and installing various couplings, such as chain-type couplings, jaw, and spider couplings, elastomeric element couplings, flexible disc couplings, steel grid couplings, and universal joint couplings.

Expand Training Capabilities with Custom Options

The 3-Component Coupling Shaft Alignment Training System can be customized with various options to create a training system that matches a particular industry’s or user’s specific needs. In industry, one size rarely fits all and this trainer can be tailor-made to your exact needs.

For example, the training system can be expanded with available options, such as a shaft alignment tool kit; standard and extended shim kits; laser shaft alignment systems; steel grid couplings; elastomeric element couplings; jaw and spider-type couplings; flexible disc couplings; chain-type couplings; universal joint couplings; gear-type couplings; rigid sleeve-type couplings; continuous sleeve gear couplings; a magnetic base/dial indicator set; and a DAC Worldwide electromechanical workstation.