BÖHLER AMPO

We offer seven powder types for additive manufacturing under the brand name BÖHLER AMPO.

OUR CUSTOMERS BENEFIT FROM:

Product range. From stock, we offer for the moment our standard program of seven powder types, but our product portfolio is constantly updated by new developments. For customer-specific topics, we can resort to our portfolio of about 250 steel brands. Due to our production facilities and our metallurgical expertise, it is possible to adapt alloys.

State of the art technology. Vacuum induction melting and atomization under inert gas ensure the highest product quality. The powder is produced on the latest atomization techniques and tested in-house.

Highest product quality. Depending on the steel grade, nickel-base alloys, and customer requirements, raw materials molten under vacuum or remolten can be used. This ensures the highest quality standards and minimizes undesired impurities.

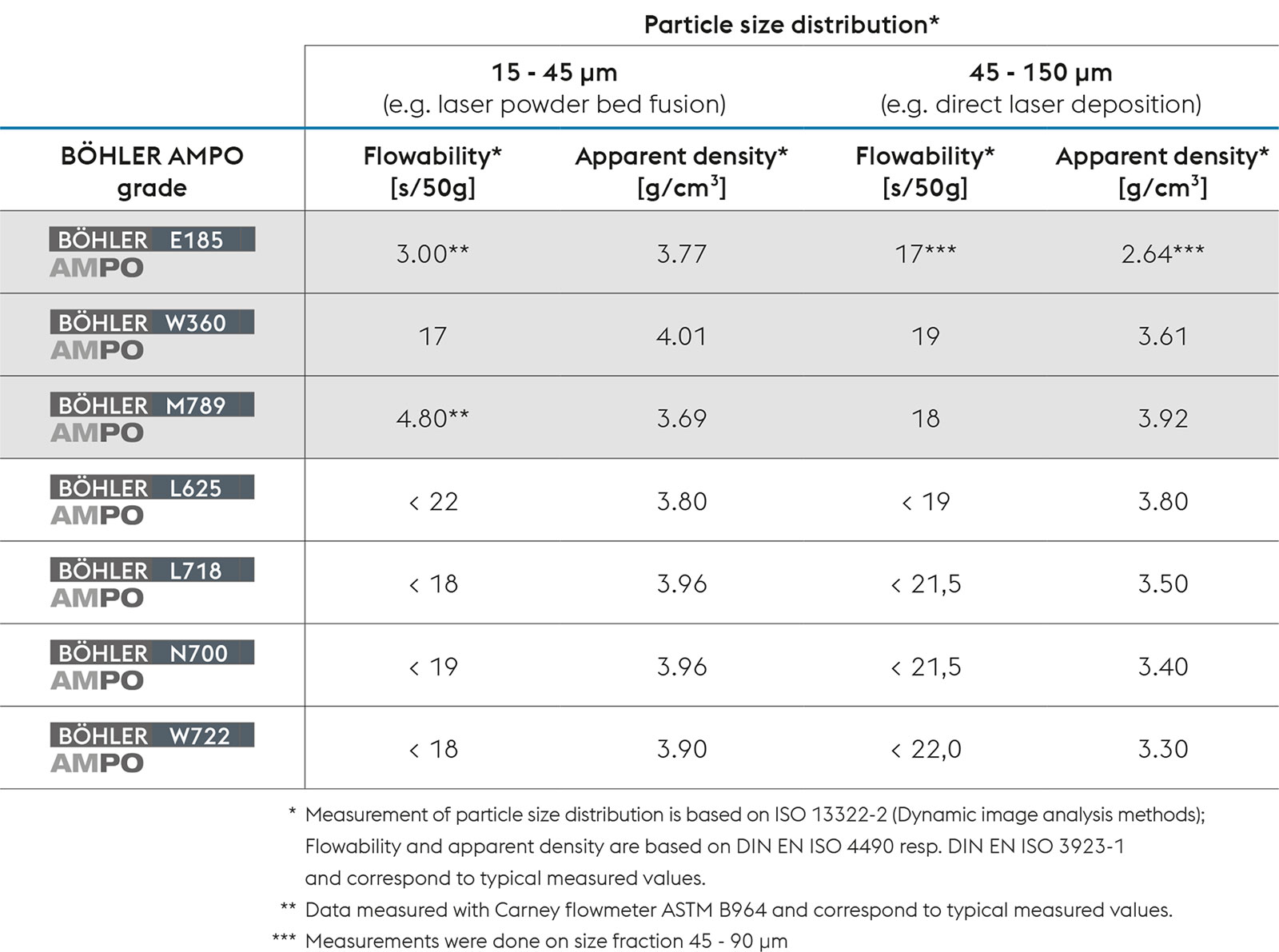

Particle size distribution. Depending on the requirements of the AM process used, we can provide the appropriate particle fraction in a range from 15 - 150 µm.

Test laboratory/ Analyses. The modern laboratories of voestalpine BÖHLER Edelstohl supply our production with important information and product parameters for process control and product certification according to test standards and customer specifications.

Global sales network. Short delivery times combined with high delivery reliability.

BÖHLER AMPO TECHNICAL DATA

BÖHLER offers powders with the right properties for every application and printing technology. In its global development and testing center, we produce test objects with 3D printing in order to acquire experience and explore new application areas for additive manufacturing of components.