Benchtop Gas-Liquid Absorption

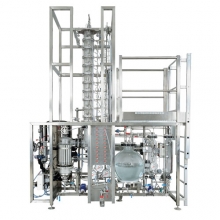

Pignat's Gas Liquid Absorption trainer (ABS/100) is a compact, benchtop unit that allows students to operate a packed gas absorption column. The absorption process, used in gas scrubbing, involves transferring material from a gaseous mixture (solute) into a liquid (solvent). This process is very common in industry for treating polluted discharge gases.

The two phases (liquid and gas) become intimately mixed as they pass through the column packing, allowing components from the solute to migrate from the gas phase to the liquid phase. The solute-enriched liquid phase is drawn off at the base of the column, while the depleted gaseous phase leaves from the head of the column.

The trainer allows students to study the absorption of NH3 or CO2 in water, determine the material balance of the gaseous solute, influence of operational parameters on efficiency of the column, thermal balance, packing factor, and more. Educational handbook and technical manual included.

Features

- Mass transfer between gas-phase and liquid-phase

- Tabletop unit

Instrumentation

- 2 pipe U manometers

- 2 water flowmeters

- CO2 flowmeter

- Air flowmeter

Specifications

- Liquid-phase feeding pump, magnetic drive, sampling valve

- Glass column, in three parts: (1) column head, with SS plate equipped with a liquid flow diffuser; (2) packed section, glass Raschig rings 6×6, SS packing support; and (3) column bottom, SS plate

- Enriched liquid-phase magnetic pump

- Receiver, polyethylene, draining valve

- Graduated glass funnel, 2.5L