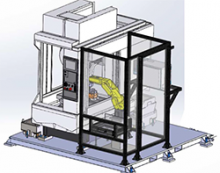

Automotive High-Volume Cell Courtesy of Meredith Machinery

FANUC’s Authorized System Integrator Meredith Machinery built and designed a high-volume automotive cell using a FANUC M-20iD/25 to pick and place, FANUC iRVision to orient and inspect, and two fully integrated FANUC ROBODRILLS to drill and machine the parts.

How the system works

First, the parts are loaded on the infeed conveyor, where the M-20iD/25 picks the part and orients it onto the iRvision inspection nest. After the inspection, the M-20iD/25 picks the part and loads it into the ROBODRILL for drilling. Minimum Quality Lubricant is used in the ROBODRILL to increase tool life and OEE. Afterward, the part is placed on the outfeed conveyor and ready for processing.

Benefits

- Increased part quality

- FANUC iRVision for part orientation

- FANUC Picture for easy-to-use operator interface

- FANUC Robot PMC to save cost and availability of PLC components

FANUC M-20iD/25

Offering high performance in a small footprint, the FANUC M-20iD/25 is ideally suited to loading and unloading machines and parts handling and positioning in crowded factory environments. For best access, it features a compact arm and wrist and, thanks to its new improved design and drive train, offers significantly higher axis speeds and motion performance.

FANUC ROBODRILL

ROBODRILL’s compact design and easy accessibility from all sides make it ideally suited for trouble-free machine tending. Adding machine tending robots is easy thanks to our Quick and Simple Startup Packages. All FANUC products speak the same language and share common servo and control platform – something that makes learning and operation extremely easy.

About Meredith Machinery

Meredith Machinery is an Indiana and Kentucky CNC Machine Tool Distributor, being the area’s only full-line CNC Machine Tool Distributor with 20+ years in Business.