FANUC America

Global Leader in Industrial Robotics and Automation

FANUC Robotics industrial robots and automated systems cover a wide range of applications for the aerospace, automotive, consumer goods, food, metal fabrication, medical, pharmaceutical, solar panel, and many other industries. FANUC Robotics America is the industrial robotics industry leader.

As the number one supplier of intelligent robots, there are more FANUC robots working in manufacturing and industrial facilities than any other brand. The FANUC Robots Certified Education Robot Training Cell is extremely valuable to trade schools, high schools, community colleges, and engineering schools. Tech-Labs is proud to be FANUC Robotics exclusive Education Authorized Reseller in Texas and Oklahoma.

Visit FANUC:

FANUC Robotic's Website | FANUC Certifications

Stay informed - Make sure to follow FANUC!

-

FANUC America now offers Certified Education Robot Training (CERT) to qualifying High Schools, Community Colleges, and Universities. With FANUC America's educational robots, students can learn to utilize the latest automation technology while applying Science, Technology, Engineering, and Math. Industrial robotics training in the classroom can safely be achieved through the CERT program. FANUC America provides the necessary training to the instructor as well as a curriculum to introduce students to robot applications.

-

Item Number:D73F-0320-PB00Experience the cutting-edge in CNC machining simulation with FANUC's D73F-0320-PB00 simulator. Equipped with real kinematics, live machine movement, and advanced features like collision detection, immerse yourself in a true-to-life machining experience. Discover the power of virtual milling or lathe operations with our software-only version for seamless integration. Get ready to revolutionize your CNC training!

-

Item Number:CR-7iA/LAllows for a collaborative operation with human operators due to no need of safety fences, and enables to locate the robots close together in the manufacturing processes where operators also work, with using the compact size.

-

Item Number:FANUC ER-4iADesigned with students in mind, this all-in-one robotics-training bundle enables individuals to gain first-hand experience of programming and operating cutting-edge industrial robots. Package content is highly relevant for modern factory applications and contains everything instructors require to teach students to program and operate robots.

-

The FANUC Fenceless Collaborative Cert Cart was developed by combining FANUC DCS Position and Speed Check software with an Allen Bradley SafeZone Mini Safety Laser Scanner. The result is FANUC’s NEW FENCELESS CERT Cart, which still fits through a standard door and runs off 110V power. The FENCELESS cart allows a greater work envelope and introduces students to the latest integrated safety products from FANUC and Allen Bradley.

-

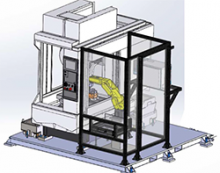

Students trained on ROBODRILL products will be more productive. Excellent repeatability makes the ROBODRILL suited for milling, drilling, tapping, and boring with flexibility, versatility, and reliability. Specific ROBO DRILL education packages have been configured for the needs of educational institutes teaching 3-axis and 5-axis machining, robotic machine tending, and Connected Smart Manufacturing (CSM).

-

Item Number:α-D14MiBThe new-generation FANUC ROBODRILL promises unrivaled quality and precision at great hourly rates. At the heart of every ROBODRILL is a patented high-speed tool changer that can carry 21 tools and offers the best reliability in its class.

-

The FANUC Robot Integration Package (25098) allows customers to use a FANUC industrial robot with Amatrol’s 870-series mechatronics stations. This package contains a module enclosure that includes PLC and FANUC interface cables along with a customized program to integrate a customer-supplied FANUC robot with the mechatronics system. Additional features include customized gripper tooling and a safety guard assembly to protect learners.

-

Item Number:LMV-400 CNCThe Levil CNC certification milling cart enables students to gain exposure to milling practices, including on-machine programming, set up and operation. The small footprint with easy access allows portability, eliminating intimidation that much larger machines can impose on students when first entering CNC programs. The portable machine runs on a standard single-phase 110vAC outlet and is capable of being moved from classroom to classroom through a standard doorway.

-

Item Number:LTC-30The LTC-30 is a robust system designed for the industrial production of small parts. You will not find another lathe at this size that will give you the same rigidity and precision while cutting a wide variety of materials.