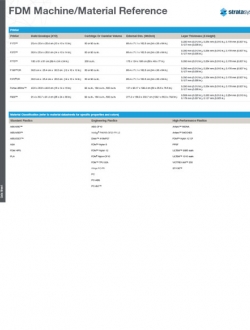

ULTEM™ 9085 Resin

High-performance FDM PEI thermoplastic.

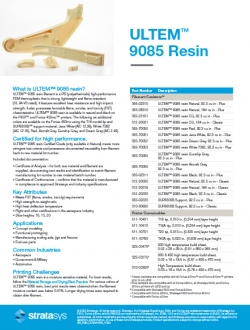

ULTEM™ 9085 filament is a high-performance thermoplastic with excellent physical and mechanical properties for high-demand and specialty applications using FDM technology. It is among the strongest of Stratasys FDM materials and its high-strength-to-weight ratio makes it well-suited for high-strength/low-weight applications. Additionally, ULTEM™ 9085 filament possesses high impact resistance and excellent chemical tolerance and meets multiple transportation industry standards for flame, smoke, and toxicity requirements.

ULTEM™ 9085 filament certified grade has the same characteristics but also has traceability documentation and meets more extensive and stringent test criteria. A Certificate of Analysis lets users track the filament back to the raw pellet stock. A Certificate of Conformance identifies compliance with approved Stratasys and industry standards. This makes ULTEM™ 9085 filament-certified grade highly suitable for industries that require a higher level of material traceability.

Besides the standard colors of Natural and Black, additional colors of ULTEM™ 9085 filament are available from the Stratasys Validated Material portfolio. Some of these colors match specialized industry and original equipment manufacturer design specifications. See the ULTEM™ 9085 resin material data sheet for specific material properties. These additional colors are listed below:

- Red

- Aircraft Gray

- Gunship Gray

- Dream Gray

- White 7362

- Jana White

Typical Applications

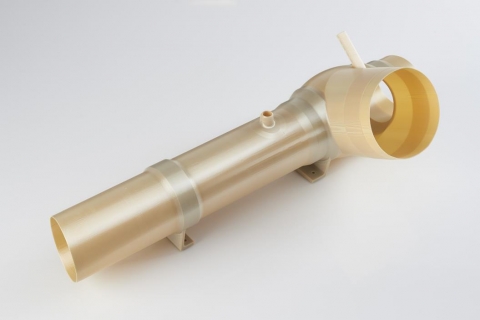

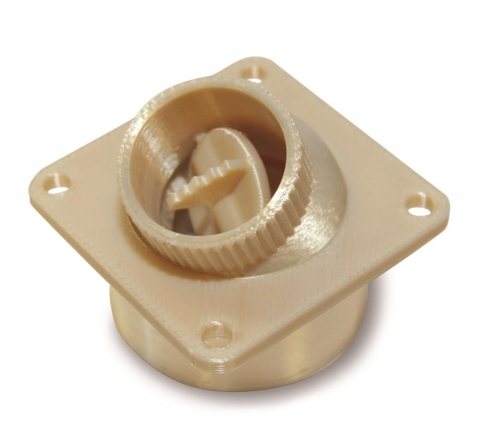

Prototyping

Functional prototypes for high-demand applications.

Tooling

Jigs, Fixtures, End-of-arm tools, Composite molds.

Production Parts

Low-volume production and highly-customized parts.

Performance Properties

Ultimate Tensile Strength

ULTEM™ 9085 resin : 69MPa(9950PSI)

Nylon 6 : 68MPa(9800PSI)

PC : 57MPa(8300PSI)

Nylon 12 : 46MPa(6650PSI)

HDT (Heat Deflection Temperature)

ULTEM™ 9085 resin : 153°C(307°F)

PC : 127°C(261°F)

Nylon 6 : 93°C(199°F)

Nylon 12 : 55°C(131°F)

Benefits and applications for ULTEM™ 9085 filament

Fortus 400mc, Fortus 380, Fortus 900mc