The Benefits of Portable Welding Simulators

Unlocking the Future of Welding Training

Welding is a crucial skill in various industries, from construction and manufacturing to automotive and aerospace. The demand for skilled welders continues to rise, making it essential for individuals to receive effective training. Traditional welding training methods involve hands-on experience, which can be costly and time-consuming. However, portable welding simulators are revolutionizing how aspiring welders acquire essential skills.

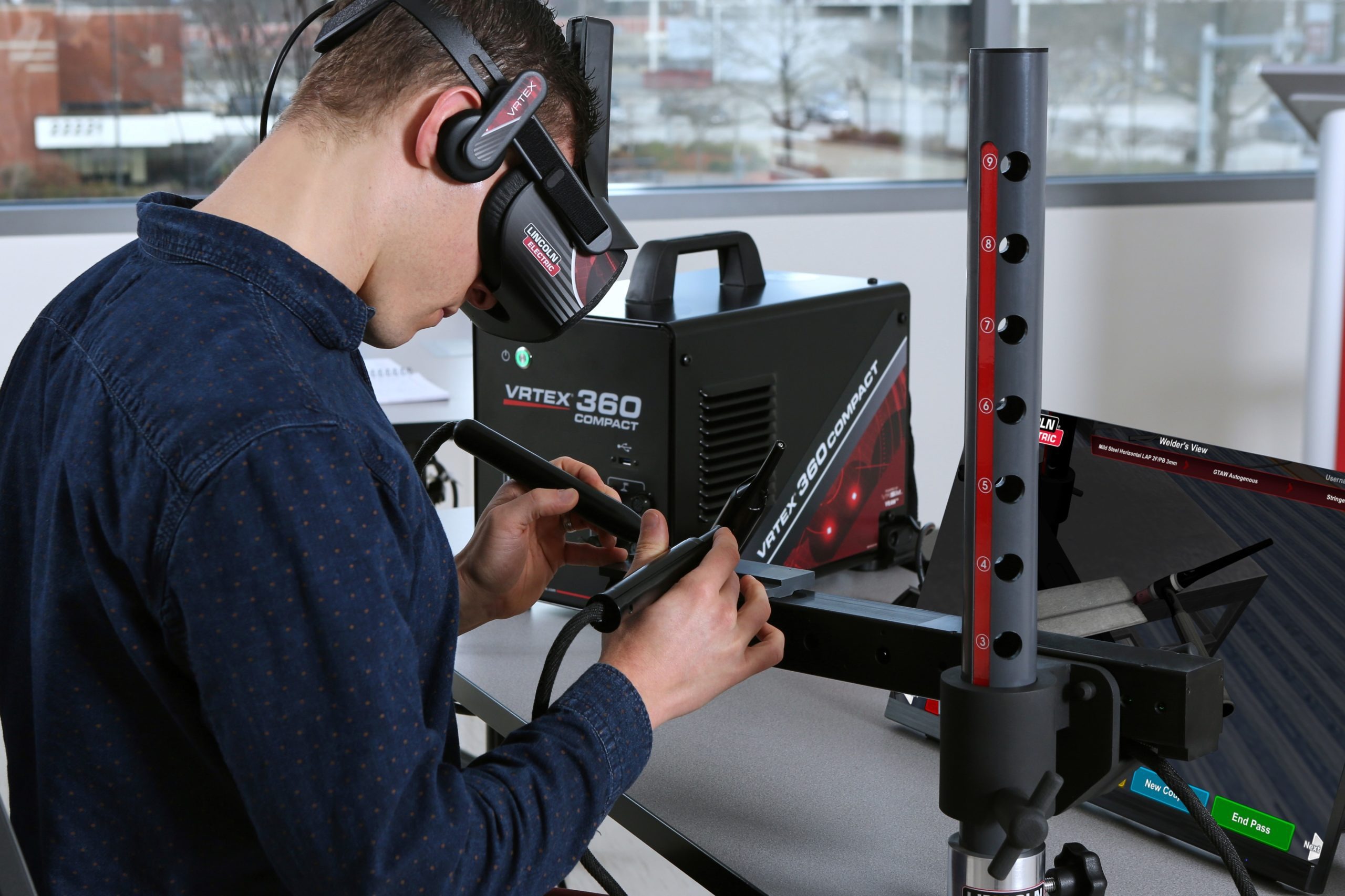

In this blog post, we will explore the benefits of portable welding simulators and spotlight the Lincoln Electric VRTEX 360 Compact as a game-changing tool in welding education.

Advantages of Portable Welding Simulators

One of the primary advantages of portable welding simulators is their cost-effectiveness. Traditional welding training requires a dedicated welding booth, materials, and safety equipment, all of which can be expensive. In contrast, portable welding simulators significantly reduce the cost of training. These simulators eliminate the need for physical materials, and the virtual environment allows for unlimited practice without consuming actual welding resources like metal and gas.

Welding is inherently dangerous, involving high temperatures, sparks, and hazardous fumes. Safety is a paramount concern in welding training, especially for beginners. Portable welding simulators provide a safe learning environment. Trainees can practice their welding skills without exposure to these risks. This not only reduces the potential for accidents but also builds confidence and competence in a controlled setting before working with real materials.

The portability of welding simulators allows for training at any location and time, making it highly convenient for both students and instructors. Whether in a classroom, workshop, or at home, learners can access the simulator, which can be set up with minimal effort. This flexibility facilitates a more personalized and efficient learning experience.

Modern welding simulators like the Lincoln Electric VRTEX 360 Compact offer realistic feedback and assessment features. Trainees can receive immediate feedback on their welding techniques, including information on arc length, travel speed, and torch angle. Instructors can track progress and tailor their guidance accordingly, helping learners improve their skills faster.

Portable welding simulators have been shown to accelerate the learning process. Trainees can repeat exercises and perfect their technique without the constraints of material costs or time limitations. This iterative approach enhances muscle memory and hones welding skills more rapidly.

Welding encompasses various techniques, such as MIG, TIG, and stick welding. Portable welding simulators can simulate all these welding methods, allowing trainees to become proficient in multiple techniques. This versatility ensures that welders are well-prepared for a variety of job opportunities.

Spotlight: Lincoln Electric VRTEX 360 Compact

Among the many portable welding simulators available in the market, the Lincoln Electric VRTEX 360 Compact stands out for several reasons:

The VRTEX 360 Compact offers a highly realistic welding simulation experience. Trainees can practice various welding processes and positions, gaining valuable experience before working on actual projects.

The simulator provides detailed feedback on weld bead quality, travel angle, and other critical welding parameters. This helps users identify areas for improvement and refine their skills.

As the name suggests, this simulator is compact and portable, making it easy to transport and set up in different training environments.

The VRTEX 360 Compact reduces the cost associated with traditional welding training by eliminating the need for consumable materials and reducing equipment wear and tear.

It allows for training in multiple welding processes, including MIG, TIG, and stick welding, ensuring a well-rounded welding education.

Portable welding simulators like the Lincoln Electric VRTEX 360 Compact are transforming welding education by making it more accessible, cost-effective, and safe. These simulators provide a realistic and convenient learning experience, accelerating skill development and helping trainees become proficient welders. As the demand for skilled welders continues to grow, investing in portable welding simulators is a wise choice for individuals and institutions looking to prepare the workforce of the future.